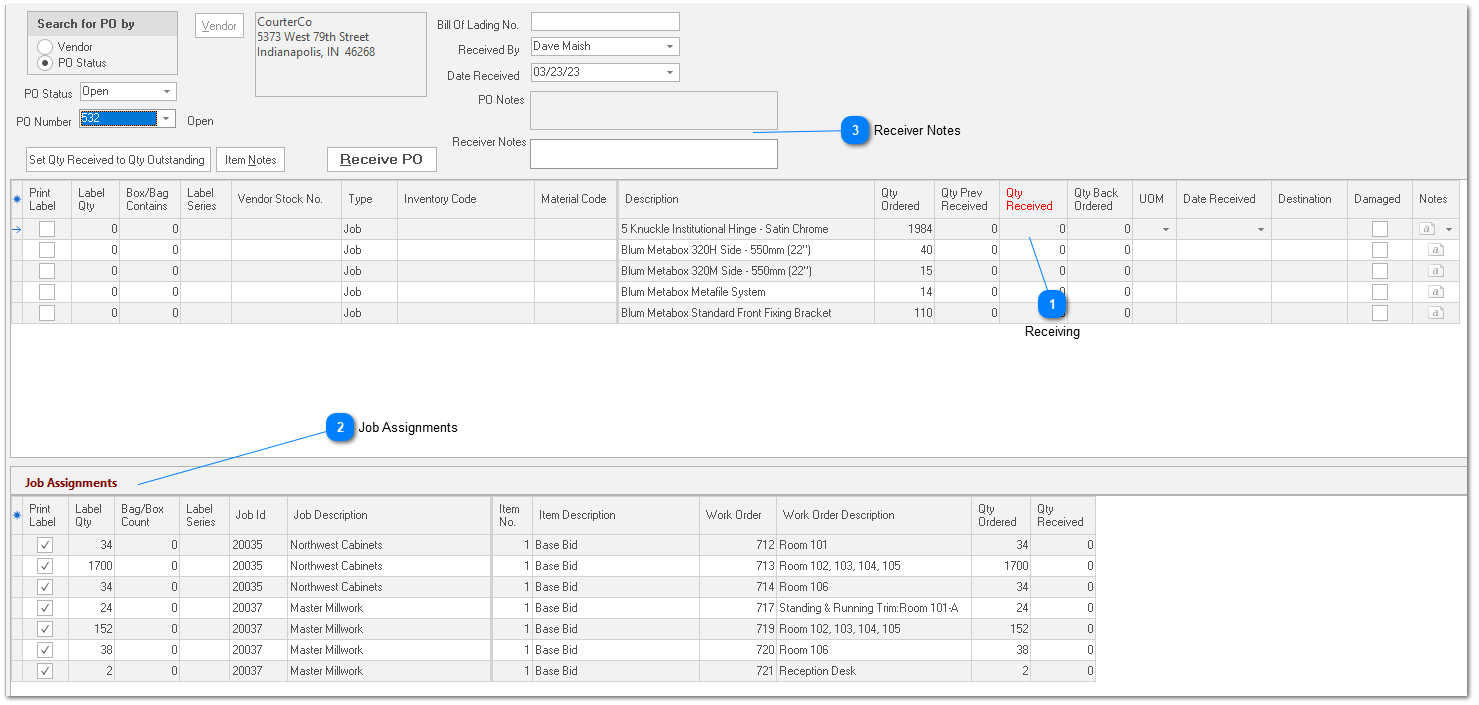

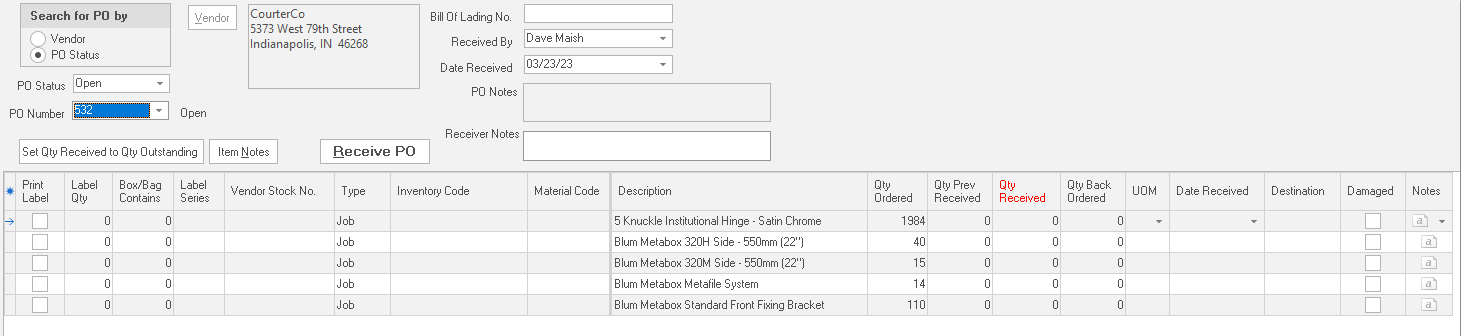

Displaying the Receiving Form

We’ve designed the ‘Receiving’ form to be straightforward and easy to use. If you wish, you can install ShopPAK on a PC out on your shipping / receiving dock and train a shop employee to receive, as well as, ship products directly with ShopPAK. A nice feature is that you can set up their security privileges to only show the Receiving and Shipping tabs.

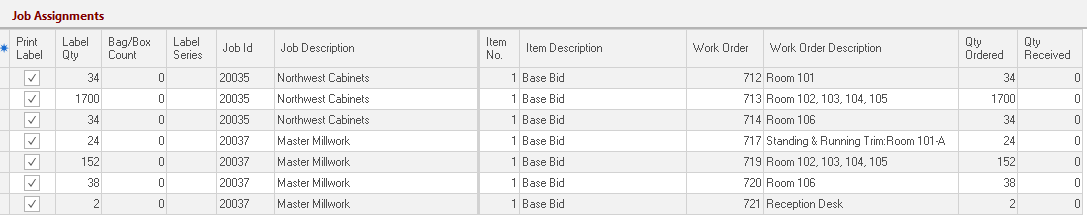

If you created a job assignment on the PO, it will display the details here.

Print Label

Place a check in checkbox if you want ShopPAK to generate a material label for the selected job assignment. Only allowed if the PO Type is ‘Job’ or ‘Reserved’. For PO Type ‘Stock’, use the label columns in the PO Item grid. We cover material label generation on page 21 of this chapter..

Set your ‘print label’ defaults via the “ShopPAK Options” dialog box by selecting Define | ShopPAK Options | Purchasing from the menu. Check the PO Item types that you want ShopPAK to automatically place a check into ‘Print Label’ checkbox.

Label Quantity

If ‘Print Label’ is turned on, defaults to job assignment ‘Quantity Ordered’. This can be overridden when needed. Contains the number of labels you want to generate for the job assignment.

Bag / Box Contains

Additional information that prints on a material label indicating how many items are contained in a box or bag.

Label Series

Use label series to tie related material labels together. For example, if two labels are related, you might enter “1 of 2” on one label and “2 of 2” on the other label.

Job Id

Protected. Job assignment’s job id.

Job Description

Protected. Job assignment’s job description.

Item Number

Protected. Job assignment’s job item number.

Item Description

Protected. Job assignment’s job item description.

Work Order / Work Order Description

Protected. Job assignment’s work order number and description.

Quantity Ordered

Protected. Populated from the purchase order.

Quantity Received

Protected. Populated based on quantity when the order is received.

|

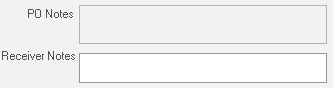

We show both purchase order notes and receiver notes on the “Receiver” form. The purchase order notes are read-only. They are shown simply to communicate information from purchasing to receiving.

The receiving notes, on the other hand, is where the ‘receiving’ employee can communicate status information back to purchasing, or record any pertinent notes about the inbound shipment. These notes show up back on the Purchasing tab when reconciling the receiver against the vendor invoice.

| ||